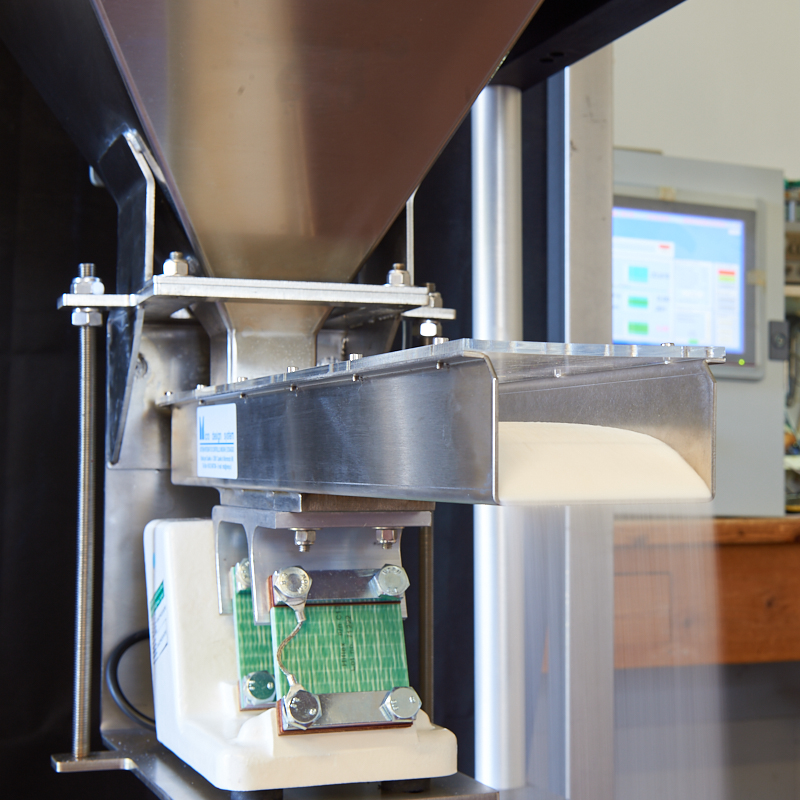

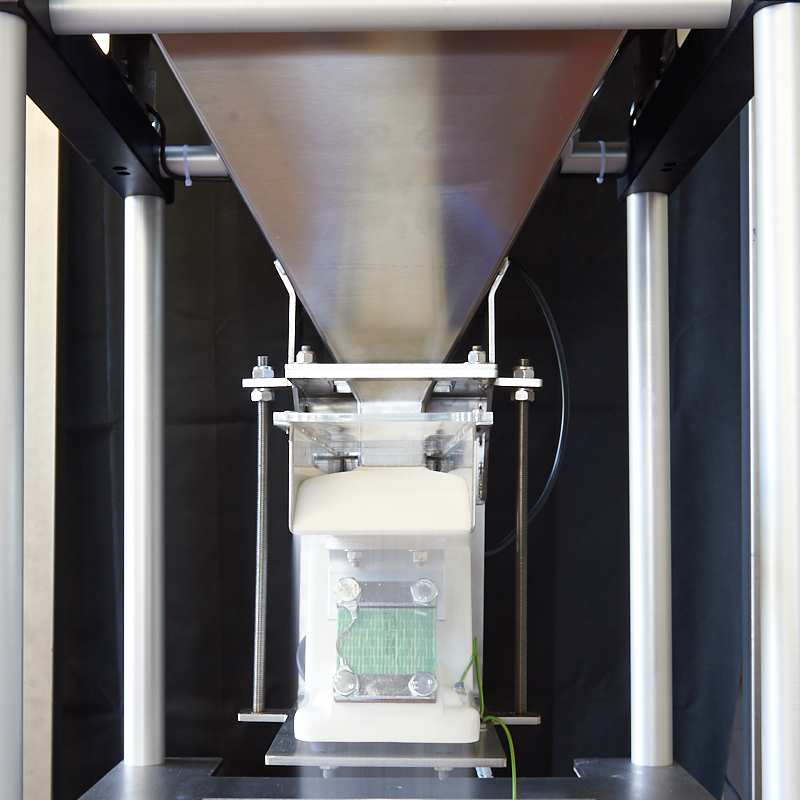

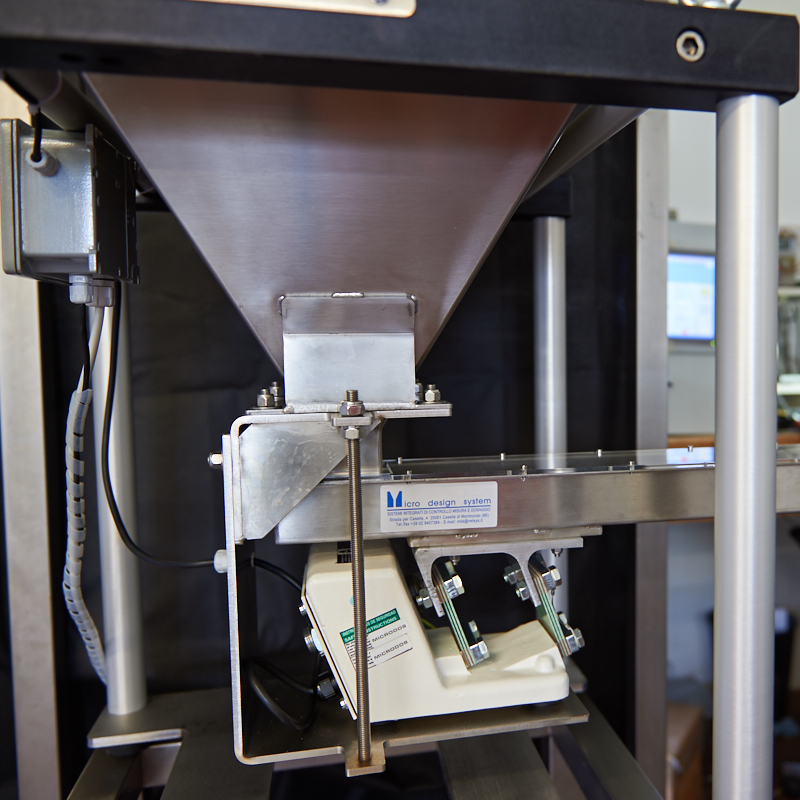

MICRODOS DOSING SYSTEM

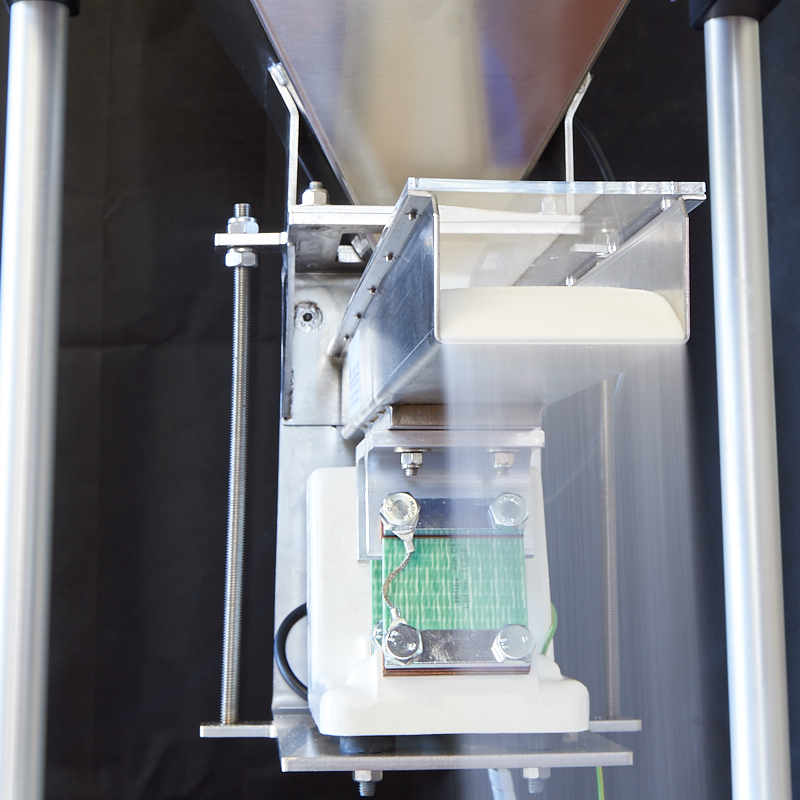

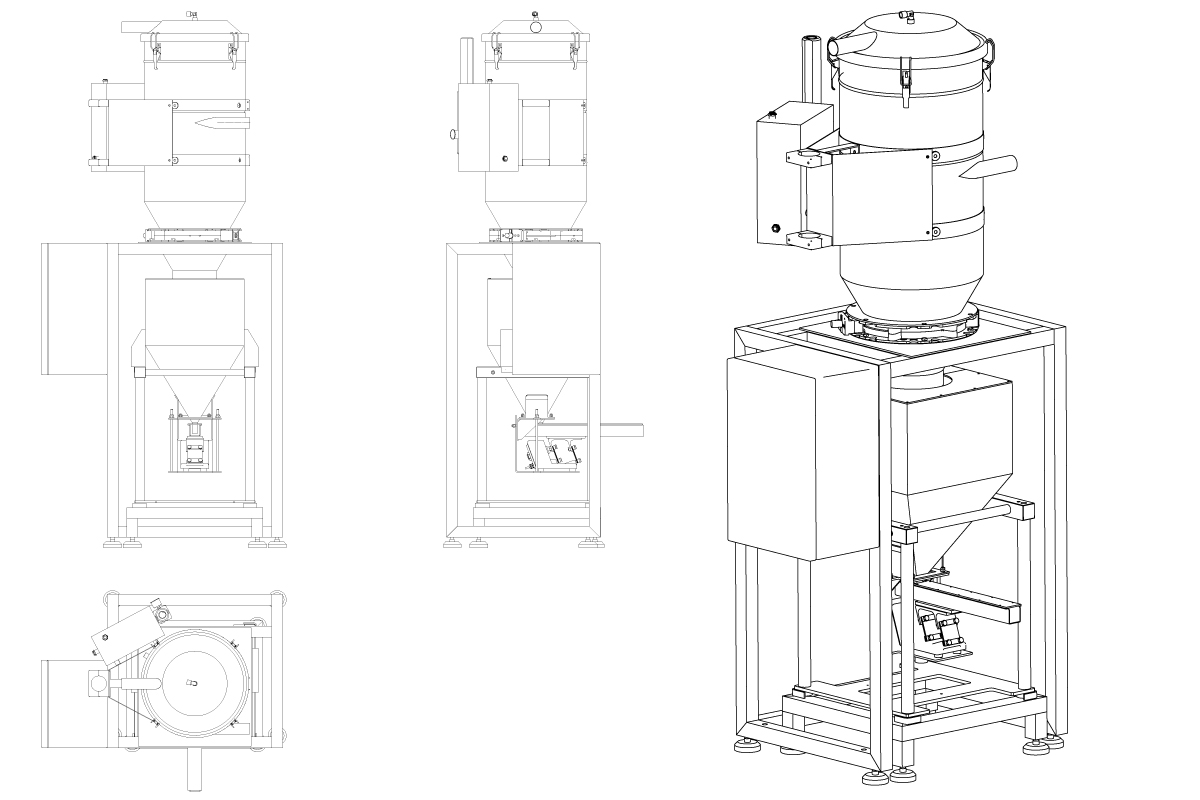

Represents the ideal solution to weight and to dose in automatic products in dust, in granules, SAP, for alimentary, confectionery, chemical and pharmaceutical industries. The various models at disposition cover a large range of weights and courses, such to satisfy every demand. Our control module, operating with a micropocessor (latest generation) and a Panel Pc (touch screen) guarantees a hight precision in the dosing, assuring an easy access of use.

Our strategy since 1990

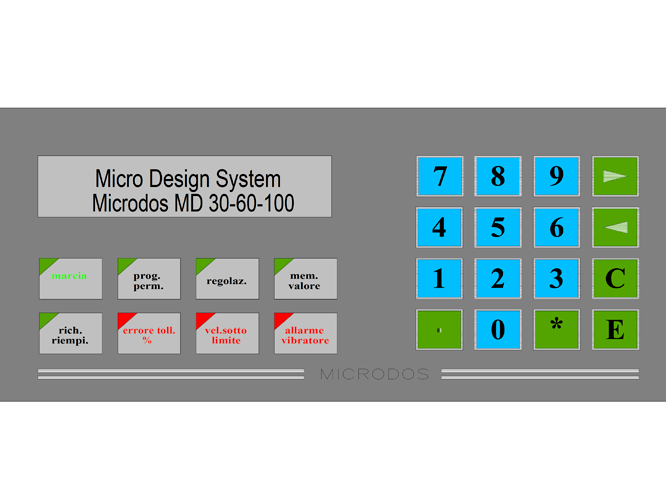

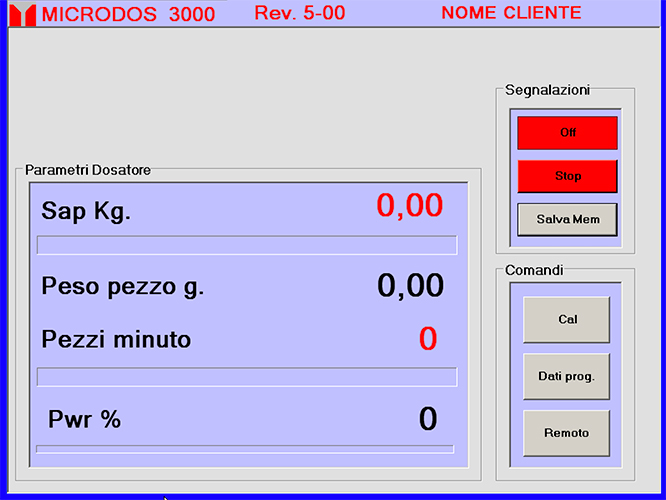

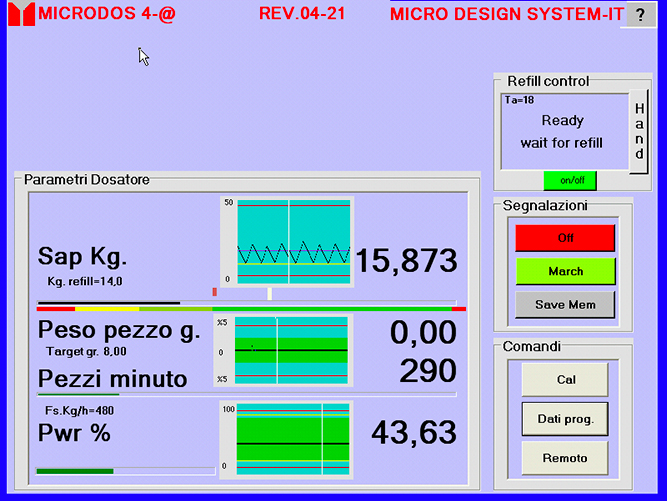

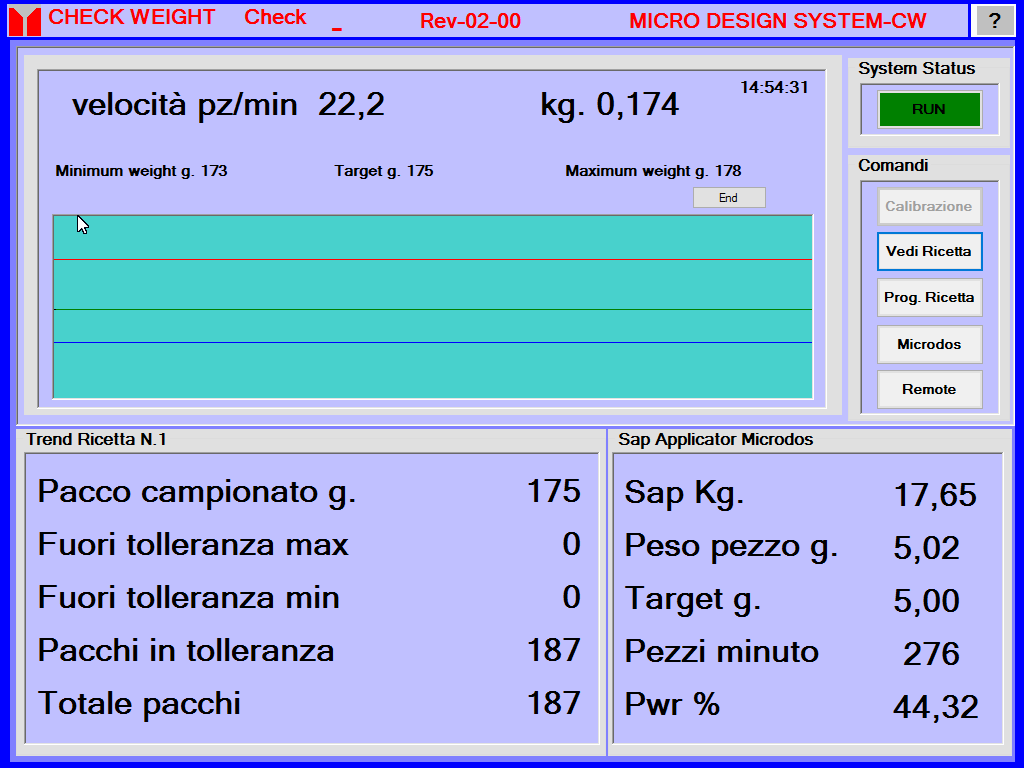

SOFTWARE EVOLUTION

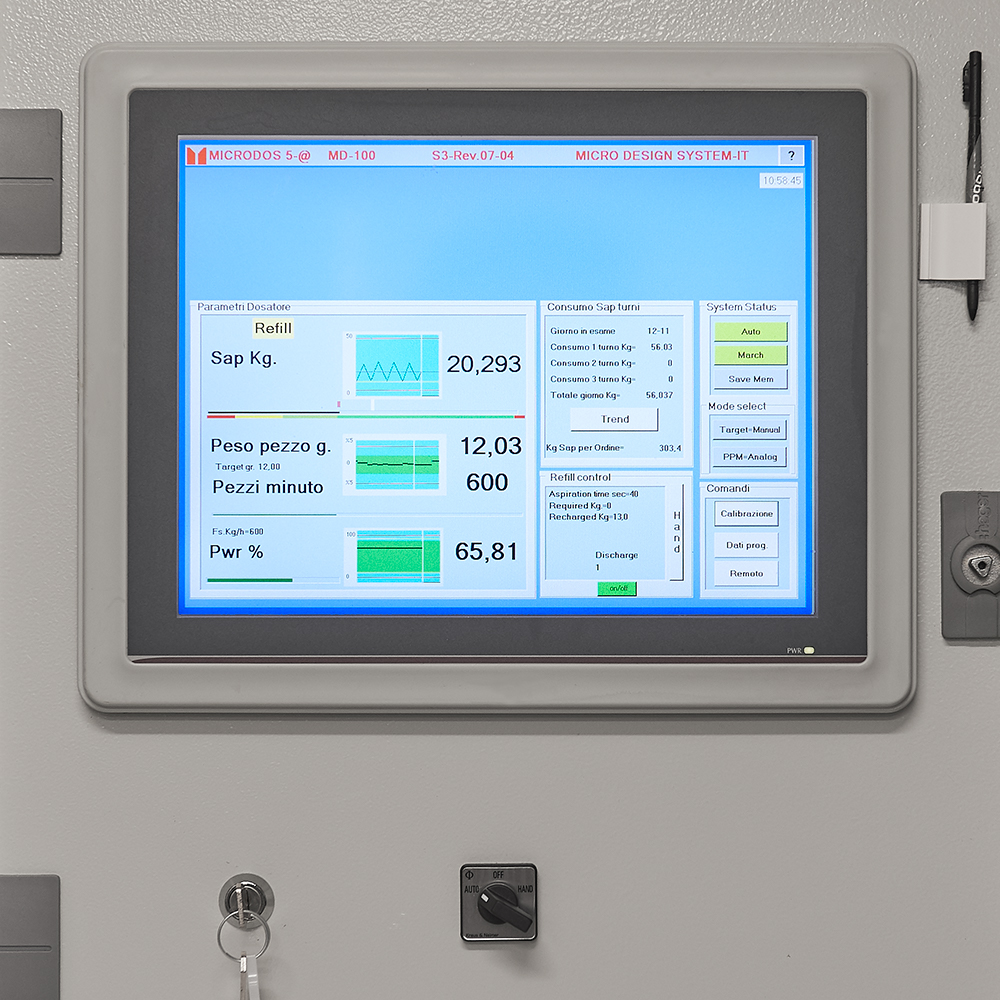

On-board dashboard always updates

1990

MICRODOS MD90

2007

MICRODOS 3

2012

MICRODOS 4 EVOLUTION

2016

MICRODOS 5 INNOVATION

2020

MICRODOS CHECKWEIGHER

TIMELESS MECHANICAL STRUCTURE

Mechanical structure of dosing system series Microdos, has been unchanged in the time. Whatever model can be updated to the last version, simply replacing the control cabinet.

Remote Assistance

CONNECTED DOSING SYSTEMREMOTE CONNECTION BENEFITS

– Connecting the Microdos to internet, you will have at your disposal our remote assistance and software updating, anywhere you are

– You could have a daily monitoring by a specialized technician, with a whole experience and abilities to guarantee you optimizations

MICRODOS 5 INNOVATION

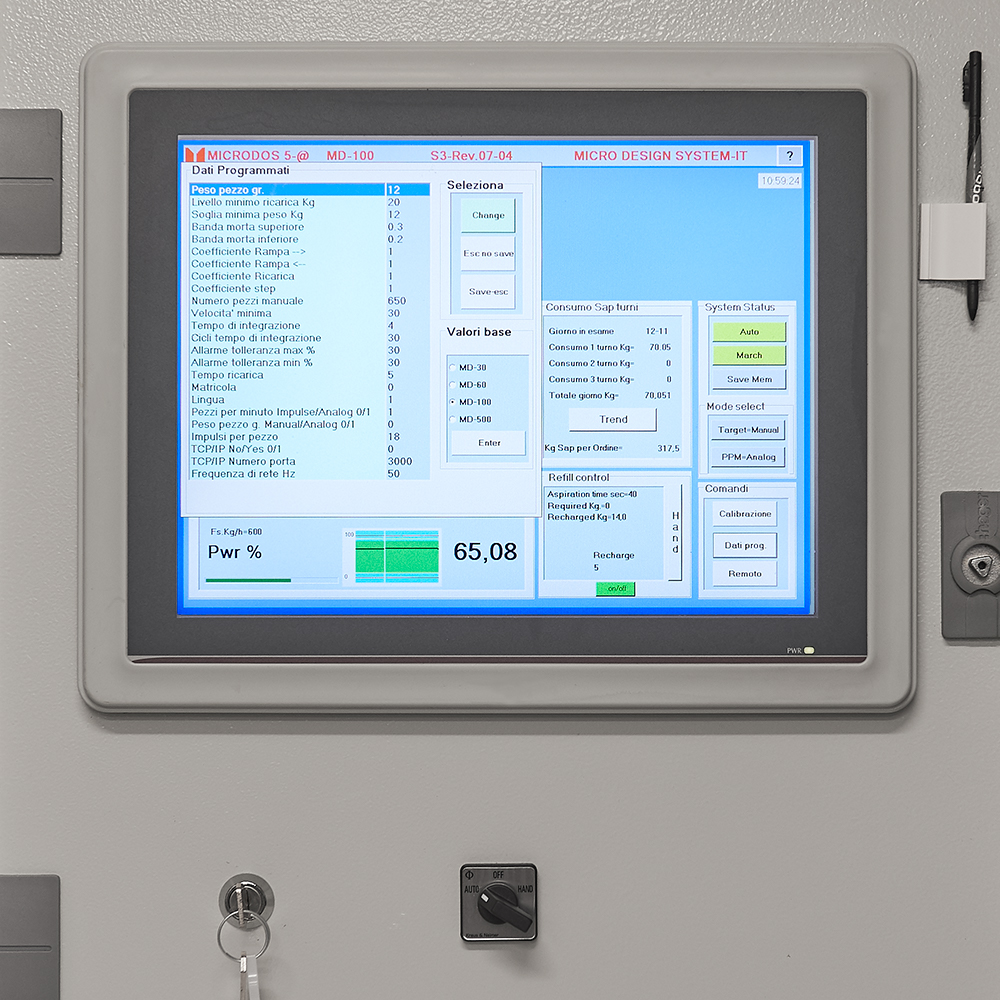

Microdos-5 born to answer to the demands of the most careful clients to the technological innovation and meet a quality control more and more severe

Easy data-entry

TCP/IP Protocol – Dialogue with Microdos Panel directly from your PLC through Tcp/Ip protocol. In this way, user can send to Microdos the following parameters: “weight piece gr”, “speed – ppm “ and “start & stop” and receives as reply above PLC other datas as Weight in the hopper, piece weight measured and a full diagnostic

Dynamic Autocalibration – Microdos autocalibrates itself during the functionning each 8 seconds to adjoust to external changes (temperature, damp, Sap specific weight)

Refill System management (automatic) – microdos can manage its “refill system”. User can simply insert the quantity of weight requested for each recharge and Microdos calculates autonomously all the parameters to reach the required weight

Cup test for an accurate control – User can sample:

– the Sap quantity supplied by Microdos in a defined time (static way)

– defined number of diapers (dynamic way)SAP consuption per workshifts – User can insert production workshifts and check the quantity of Sap used during each shits and the total quantity for day of production

SAP consuption per order – User can select the date of start order (production) and Microdos counts Sap quantity used till the end of the production

Trend – Microdos saves its functionning datas (target grams, piece weight supplied, pwr%, piece per minute, Sap Kg. presents in the hopper, carried recharges) each 4 seconds to have a daily trend, preserving historical datas for one month

Saving datas – All the saved datas can be visualized directly on the Microdos Panel Pc or from your net or more can be saved in a pendrive for an accurate analysis post-production

TECHNICAL SPECIFICATIONS

MICRODOS 5 INNOVATION

Language:

- italian

- english

- spanish

- portuguese

- french

Visualization:

- HMI colour 12″

Userl line interface:

- digital

- analogic 0/10 V

- TCP/IP protocol

Alarms exit:

- digital exit PNP/NPN

- TCP/IP protocol

Power:

- net 220V +/- 10% 50/60Hz